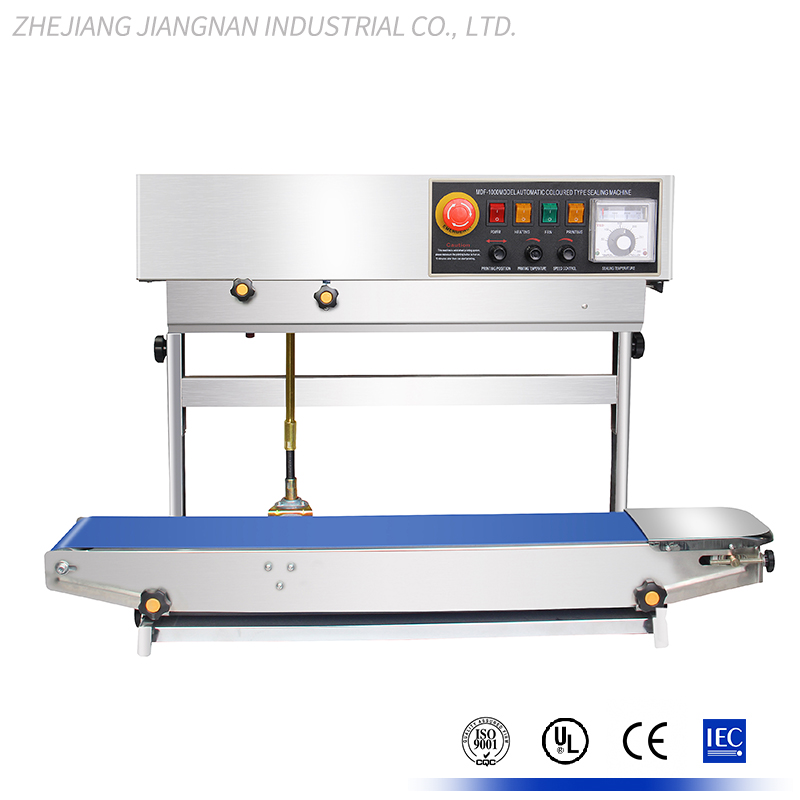

DBF770A Painted Body Continuous Band Sealer

- Category :Band Sealers,Rotary Sealers,Continuous Sealers

- E-mail :jiangnan@jn-pm.com

- Phone :+86-577-88791178

- Mobile :+86-188 5785 8073

- QQ :

Band Sealers, Rotary Sealers or Continuous Sealers

Hand impulse sealers are generally the entry models into heat sealing plastic bags and then as volumes increase, you may upgrade to a foot switch operated heat sealer. But if you require more speed then the next consideration should be a rotary continuous band sealer. The band sealers are easy to use once the temperature and conveyor speed have been set then the sealer can operate for long periods of time. The maximum speed is normally limited by the speed an operator can feed the sealer, you may be able to achieve more than 12 bags per minute (5000+ per day).

You will produce a range in sizes and prices in vertical and horizontal models, some of the smaller band sealers are table top mounted suited for smaller pre made bags. The larger machines are normally floor standing which are suited for larger bags. Useful options are ink or embossed printing of coding.

Rotary continuous sealers are designed for premade, single or multilayer plastic bags including foils and craft paper laminate.

Vertical

The vertical band sealers are ideal for flow-able products like powder, liquid or solid products that would spill if sealed lying flat. The height of the packed bag will govern the size of the band sealer. The bag must be measured when filled with the product as the filled bag is not normally as tall as the empty bag. The table top machines are normally suitable for bags less than 300mm in height and lower weights and some models can be converted into horizontal mode. Floor mounted machines should be considered for larger heavier bags.

Horizontal

Horizontal band sealers are not suitable for flow-able products like powder, liquid, or solid products that would spill if sealed lying flat. The height and weight of the packed bag normally govern the size of the band sealer. The horizontal table top machines are normally suitable for bags less than 300mm to 400mm in height as larger bags can over hang the conveyor.

Some table top models can be converted into horizontal model.

Critical spare parts for the continuous band seals are Teflon (PTFE) bands which should be replaced regularly when they break or appear blackened.

If you require a faster sealer then you will need to consider automation.

| MODEL: DBF-770A (PAINTED STEEL) | |||

| Power consumption: | 500W | Voltage: | 220V 50HZ /110V 60HZ |

| Sealing speed: | 1-12M/MIN | ||

| Temperature rang: | 0-300℃ | Printing mode | Steel emboss |

| Character: | 0-9. EXP | Sealing width: | 6-15MM (adjustable) |

| Conveyor loading | <6KG | Warranty: | 1 year |

| Dimension: | 80*38.5*30CM | After sales service: |

Video technical support online support etc. |

| Weight: | 20 | Brand: | |

| Package size: | 87*42*36CM | Sealing thickness: | 0.02-0.8MM |